The process of Aluminium corners connection

The strength and stability of aluminum doors and windows themselves (such as wind pressure resistance) are not only related to the door and window profiles, but also closely related to the door and window assembly process. Today, let me introduce the process and classification of aluminum door and window corner assembly.

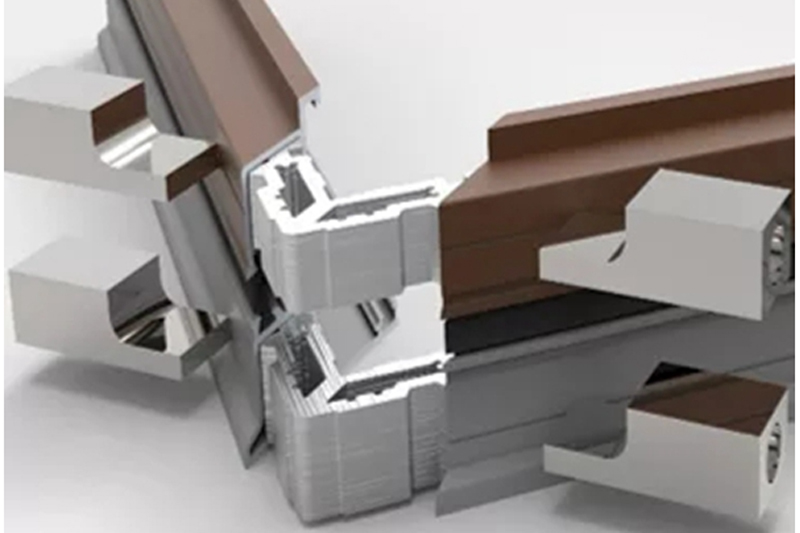

The corner assembly process for doors and windows, also known as corner connection process, requires a complete door and window to be assembled from frame and leaf structural profiles, and the key to the connection between profiles is the corner connection (that is, using corner keys to rivet two profiles together at an angle of 90 ° or 45 °).

The function of angle assembly is to increase the angular strength of doors and windows, maintain the stability of the basic framework of doors and windows, and enable doors and windows to cope with various impact forces such as human factors, strong winds, and temperature changes. Generally speaking, the corner assembly process can be roughly divided into: active corner key process, corner crimping process, and pin injection process.

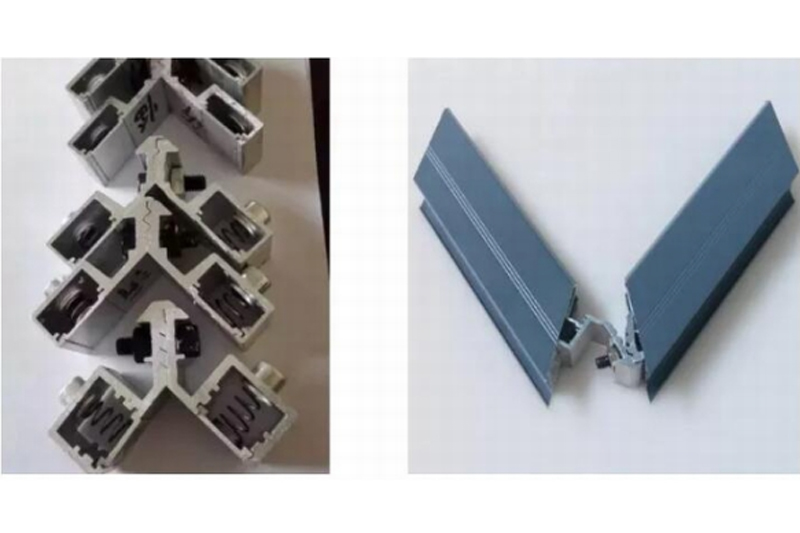

The active corner key process is connected to aluminum material through spring clips, and the doors and windows are fixed by tightening them with screws. The left and right structures are detachable and easy to disassemble, and frame, but the connection is not tight enough. Over time, water ingress can easily cause rust, loss of elasticity, or fracture of the spring part.

The corner crimping process involves applying section adhesive to the surface of aluminum profiles, inserting the corner key into the 45 degree cut profile, and connecting it through accurate machine impact and extrusion. It is seamlessly formed and not prone to water ingress and cracking. However, due to the need for corner collisions during production, on-site framing is not supported.

The corner key used in the pin gluing process is a combination of corner key film made of nail handle material and pure aluminum corner key with a thickness of 4.0-5.0mm, which has stronger toughness and stability. When assembling doors and windows, we often use weather resistant corner glue to apply and seal to enhance the overall sealing performance of the doors and windows.

Kindly feel free to contact FENSTEK if you need any aluminium window machines.

Website: www.fenstek.com

Email: fenstek@fenstek.com

TEL:+8615153148621

中 文

中 文 Japanese

Japanese Spanish

Spanish Russian

Russian Arabic

Arabic Portuguese

Portuguese French

French Korean

Korean Vietnamese

Vietnamese Thai

Thai