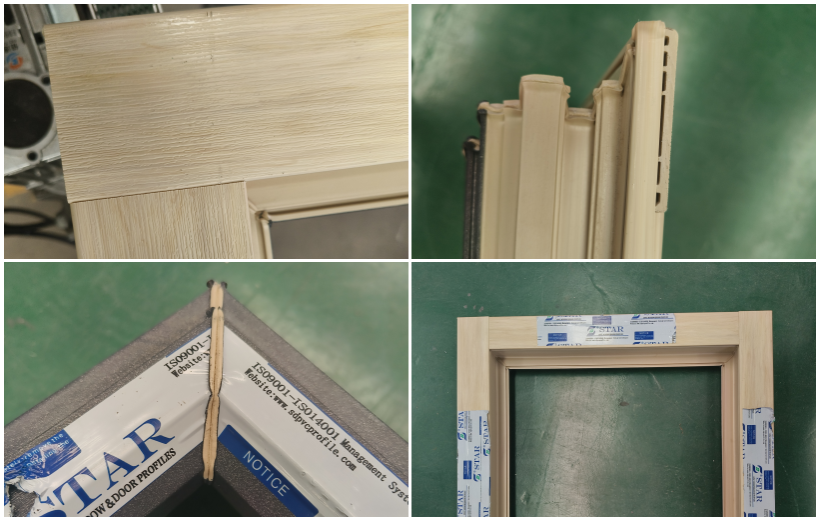

Plastic Window and Door HFL (Wood-Imitation) Right-Angle Welding Technology: An Innovative Approach

UPVC Window HFL (Wood-Imitation) right-angle welding technology represents a groundbreaking advancement in the processing of plastic windows and doors. Originating from Germany in Europe, HFL, an acronym for Holz Fenster Look in German, translates to "looking like wood." This technology is primarily applied to the external design of plastic windows and doors, aiming to provide them with a wood-imitation appearance and texture while enhancing their structural strength and aesthetic appeal. Below is a detailed introduction to this technology:

I. Technological Characteristics

Right-Angle Joints:

Unlike traditional plastic windows and doors that use 45° welding, the HFL technology employs right-angle joints, making the corners of windows and doors more robust and enhancing the overall structural stability.

Hot-Melt Laminating Technology:

Through hot-melt laminating technology, a layer of wood-grain surface is applied to the plastic profiles, giving the windows and doors a realistic wood-grain texture and elevating their aesthetic and decorative qualities.

Uniform Coloring and Laminating Process:

The profiles are mostly uniformly colored, with a finely crafted laminating process on the surface. Compared to traditional white plastic profiles, they offer a significant improvement in appearance.

II. Technological Process

Profile Selection:

Profiles that meet European process requirements are selected, ensuring that technical specifications such as cavity structure and visual wall thickness are up to standard, thus guaranteeing the welding strength and overall quality of the windows and doors.

Processing Equipment:

Specific HFL processing equipment is used, including plastic profile irregular cutting saws, plastic profile end milling machines, and plastic window and door welding machines (such as numerical control four-corner welding machines and numerical control two-position welding machines).

Cutting and End Milling:

Processing equipment is utilized to precisely cut and end-mill the profiles, ensuring dimensional accuracy and end face flatness.

Welding:

The cut profiles are joined at 45 degree according to design requirements and welded using welding machines. During the welding process, parameters such as welding temperature, time, and pressure must be controlled to ensure welding quality and strength.

Post-Processing:

After welding, subsequent processing of the windows and doors, such as removing welding slag and grinding weld seams, is carried out to improve the overall aesthetic quality and durability of the product.

III. Application Advantages

Enhanced Aesthetic Appeal:

The HFL technology grants plastic windows and doors a wood-imitation appearance and texture, making them more visually appealing and suitable for various high-end home decoration markets.

Increased Structural Strength:

The application of right-angle joints and hot-melt laminating technology makes the corners of windows and doors more solid, resulting in a more stable and reliable overall structure.

Ease of Cleaning and Maintenance:

The smooth and flat wood-imitation surface is easy to clean and maintain, reducing usage costs.

Environmental Protection and Energy Efficiency:

Plastic window and door materials inherently possess excellent thermal insulation properties. The application of HFL technology further enhances their energy-saving effects, aligning with modern building environmental requirements.

In conclusion, plastic window and door HFL (Wood-Imitation) right-angle welding technology is an innovative process that combines aesthetics, structural strength, ease of cleaning and maintenance, and environmental protection and energy efficiency. With continuous technological development and improvement, it will play an increasingly important role in the future market for plastic windows and doors.

UPVC Window HFL (Wood-Imitation) right-angle welding technology represents a groundbreaking advancement in the processing of plastic windows...

中 文

中 文 Japanese

Japanese Spanish

Spanish Russian

Russian Arabic

Arabic Portuguese

Portuguese French

French Korean

Korean Vietnamese

Vietnamese Thai

Thai